Negotiable

The date of payment from buyers deliver within days

Shandong

Long-term effective

2017-09-29 02:57

350

By certification [File Integrity]

By certification [File Integrity]

qdtongsan(Mr.)

Shandong

The west end and south side of Yangzhou Road Jiaozhou city , Qingdao,China

http://www.cnplasticmachinery.com/ http://qdtongsan.gf-job.com/

Condition: New

Application: Sheet

Plastic Processed: PE

Screw Design: Single-screw

Automatic Grade: Semi-auto

Place of Origin: Shandong, China (Mainland)

Brand Name: TS

Model Number: TS-90

Voltage: 380-415V

Certification: CE

After-sales Service Provided: Engineers available to service machinery overseas

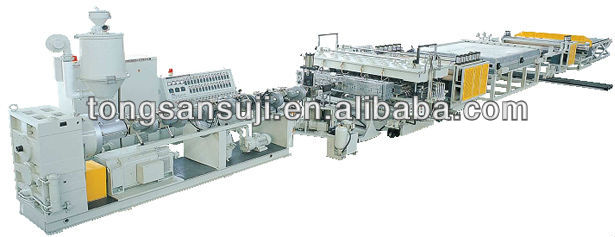

Model: SJ-90/33 SJ-120

Process: Plastic extruder

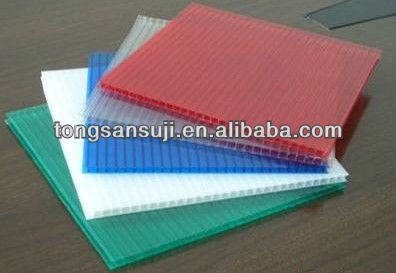

Products: PP/PE/PC hollow board

Products width: 1220-2100mm

Thickness: 2-16mm

Capacity: 300-400kg/h

| Packaging Details: | Standard packing,also can according to customer demand. |

|---|---|

| Delivery Detail: | 40days |

hollow grid sheet manufacturing plant

1) high quality and competive price

2) get CE

hollow grid sheet manufacturing plant

PP/PE/PC hollow grid board making machine

PP/PE/PC hollow grid sheet making machine

PP/PE/PC hollow grid plate making machine

This production line realizes continuous production of PP/PE/PC hollow grid board.PC/PE/PP hollow grid plate, which is applicable to construction decoration, advertisement collocation, and noise insulation of highway as well as packaging. PE/PP hollow grid plate is an indeal substitute for paper box in making packaging box. It is characterized by light weight, high intensity, dampproof, and anticorrosion. The width of the products is 1220mm-2100mm, and the thickness is 2mm-12mm.

Extruder:The specially designed screw and the advanced controlling system ensure excellent plasticization, high output and stable extruding.

Screen changer: Quick screen changer of hydraulic system ensures the short course of screen changing. Double-position combined with special sealing structure guarantee stable operation of screen changer.

Mould: Mould adopts high-quality alloy steel and throttling device to ensure even pressure of feed influent at the mould lips, and also differential action of up-down piece guarantee even thickness of the plate.

Vacuum calibrating stable: Heating exchanging and cooling system of quick speed in calibrating system alternate effectively and ordinally with vacuum system, which ensures calibrating precision. Vacuum system composes two independent subsystems and each is equipped with several fixed circulating vacuum lines of three-point type. Meanwhile, each line carries vacuum regulating system and vacuum display system that realize even and stable vacuum degree of plate surface.

Tractor: There are two tractors. The first one is of high powr, high reduction ratio, multi-roller type, well low-speed operation, high traction and is able to draw the plate up from the calibrating table evenly and synchronal. The second one is designed to remove stress, and in addition it is equipped with edge-cutting device to ensure the valid width and smooth cut of the edges.

Stress remover: The advanced large area conductive heating mode can effectively remove the stress of plate and further improve planeness of the plate.

Cutting machine: Accurate instant length-fixed cutting and automatic up-down discharging system combined with alloy steel sharp blade realize high quality of cutting