Negotiable

The date of payment from buyers deliver within days

Shandong

Long-term effective

2017-08-07 03:18

325

By certification [File Integrity]

By certification [File Integrity]

qdtongsan(Mr.)

Shandong

The west end and south side of Yangzhou Road Jiaozhou city , Qingdao,China

http://www.cnplasticmachinery.com/ http://qdtongsan.gf-job.com/

Condition: New

Application: wpc mixing

Automatic Grade: Automatic

Production Capacity: 1000kg/h

Place of Origin: Shandong, China (Mainland)

Brand Name: TONGSAN

Model Number: SHR300/600

Voltage: 380v/50hz/3phase

Power(W): 40/50KW

Dimension(L*W*H): 4.8m*3*2m

Weight: 2000kgs

Certification: CE/ISO9001

Warranty: one year(12months)

After-sales Service Provided: Engineers available to service machinery overseas

Name: wpc wood plastic powder mixer/wpc mixer/wood plastic mixing machine

Quantity of stirring blade: 3pcs

Model: hot mixing machine/hot chilling wood plastic mixer

Pot cover material: casting aluminum

Temperature control mode: electronic automatic temperature control

Material of stirring blade: 3Cr13Ni9Ti

Heating mode: electric heating and self-friction heating

QQ: 984255689

Mobile/Whatsapp: 0086-159 3109 8079

skype: nancy.yang2013

| Packaging Details: | Covered by anti-dust package then as per the export packing |

|---|---|

| Delivery Detail: | 35days after confirm the payment. |

wpc wood plastic powder mixer/wpc mixer/wood plastic mixing machine

Introduction

Developed on the basis of advanced technique, the SRL-Z series mixer is mainly used for drying, dewatering and mixing before WPC production. The spindle is with good sealing without material leakage. The heating mixer has the heating fuction of self-friction electric heating. The pot cover is adopted double-sealing layer. The cooling mixer is also adopted arched pot cover and specially-designed blade, which had been passed the test of static balance and dynamic balance. Combined with the heating mixing technique and cooling mixing technique, the SRL-Z mixer is the ideal processing equipment in WPC production. The material after being heat-mixed would go into cooling mixer automatically, then the air would be exhausted and the material wouldn't be blocked.

The main technique parameter

| Item | specification |

| Model | 500A |

| Quantity of stirring blade | 3pcs |

| Pot cover material | casting aluminum |

| Total volume | 500L |

| Mixing batter material | 3Cr13Ni9Ti |

| Mixing time | 6-12min |

| Capacity | 1000kg/h |

Article picture

Contact Info.

Article picture

WPC production machine introduction:

| Name of machine | Picture | Introduction |

| Wood pulverizer/milling machine |  |

milling/pulverizering recycled wood crust, wheat husks, rice husk into powder |

| Mixer |

|

wpc material mixing for feeding extruder |

|

machine running on youtube:

http://youtu.be/kRWPEUPqxt0

|

|

crushing recycled wood plastic into particle |

|

PVC WPC Foam Board Extrusion Line machine running on youtube:

http://youtu.be/rrYWpR7dE9o

|

|

Extruding PVC WPC board products |

|

PVC WPC Hollow Door Board Production Line machine running on youtube:

http://youtu.be/9MI6ZbWqX00

|

|

extruding wpc door panels products |

|

wpc pe/pp profile production line machine running on youtube

http://youtu.be/PnBHSb8D2eU

|

|

changing the mould can produce different model of products, like decking, pavilion, fence, bench, etc. |

Company Information

Our Machinery Processing Flowchart

Our Company & Machinery

Qingdao Tongsan Plastic Machinery Co.,Ltd. can provide machinery in high quality with good customer service .

Main business

Plastic Machinery (Plastic Pipe MachinePlastic Plate MachineWPC Profile MachineWPC Plate MachineSingle Wall Corrugated Pipe MachineDouble Wall Corrugated Pipe Machine)

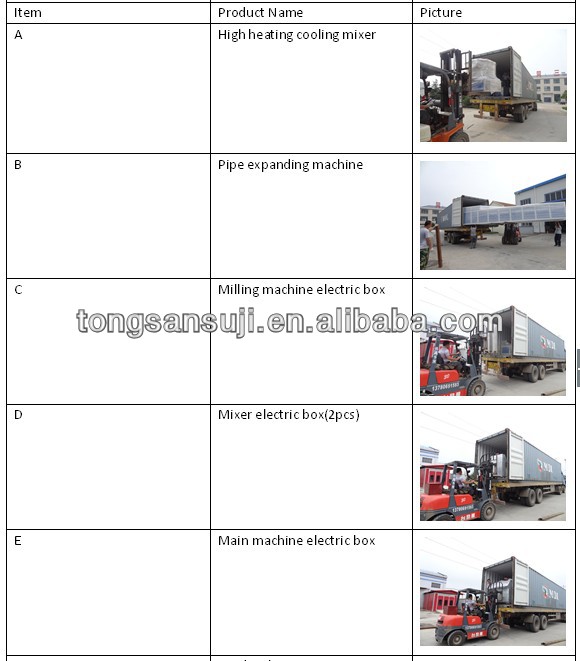

Packaging & Shipping

FAQ

Customers & Salers

Q.: Are you a trade company or a factory ?

A.: We are a factory which do business in machinery line for more than 15years.

Q.: What is the WPC production line price ?

A.: The WPC PVC foam board extruding line is about 100,000usd-150,000usd. The details price and further information, Please add my skype: nancy.yang2013 and send an enquiry to me. (Ms. Nancy)

Q.: Visit factory ?

A.: You only need to confirm the time and your reaching place then we will arrange to pick up you from airport or hotel to our factory. Welcome you !

Q. : Delivery time ?

A.: We have the WPC machinery line in stocks, after our Account Department confirm your payment, we will delivery goods within 40da

Q. : Payment terms ?

A.: 30% of total amount should be paid by T/T as down payment, the balance (70% of total amount) should be paid before delivery by T/T or confirmed irrevocable L/C at sight.

100% confirmed irrevocable L/C at sight also can be accepted by our factory

Q. : Installant and test ?

A.: Seller send technician to buyer’s factory installed and tested the machinery, teach the workers

how to use it. The buyer should pay the fee of tickets, accommodation and the salary of workers 80dollars

per day per person.

Our Services

1. We will provice the Feasibility Analysis Report for the wood-plastic project.

2. We will provide the model selection and technical parameter for wood-plastic machinery.

3. We will provide the design for the plant and electric power accounting for the facilities.

4. We will provide the design for wood-plastic formular acording to the product requirements.

5. We will provide the technology of wood-plastic product surface treatment.

6. We will provide technique training for operator.

7. We will provide solution for the practical problem during the production.

8. We will install and test the machine for free.

9. We will provideturnkey project to customers.

Service before order

1. Supply the Turnkey Project, including the machine layout and workshop layout.

2. Supply the Free samples for reference and check.

3. We produce the spiral/corrugated pipe mould by factory, we can produce different size of mould as for your drawing.

Service after order

a. Test the machine before delivery freely.

b. Engineers to go to install and test the machine in customers' factory.

If there are any interest to you, pls contact us immediately.

Looking forward to receiving your early enquiry.

Nancy

skype: nancy.yang2013

salernancy#tongsanextruder.com

nancy#wpcmachinery.com

If there are any interest to you, pls contact us immediately.

Looking forward to receiving your early enquiry.

Nancy

skype: nancy.yang2013

salernancy#tongsanextruder.com

nancy#wpcmachinery.com